Effect of storage period of common sunflower oil oleogels on their thermal behaviour and oxidative deterioration

DOI:

https://doi.org/10.26461/25.04Keywords:

structuring, waxes, stabilityAbstract

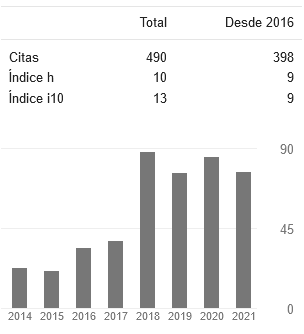

Oleogels are particularly important as they can be used as a replacement for fatty materials for food use, although their use is conditioned by their shelf life. In this context, thermal properties of sunflower oil (AG) oleogels with beeswax (CA) and carnauba wax (CC) as structurants at different concentrations were studied by differential scanning calorimetry, and their oxidative deterioration at room temperature as a function of storage time. According to oleogels melting thermograms, the increase of the structurant concentration caused an increase in the peak temperatures. The ranges associated with the destructuring temperature were between 26.3 and 60.8 °C and 35.9 and 86.1 °C while the corresponding enthalpies ranged from 1.5 to 6.5 J/g and 3.3 to 13.3 J/g for CA and CC, respectively. The results for oxidative deterioration were higher for the CC oleogels. This indicates that CA oleogels have a higher resistance to oxidation and thus higher oxidative stability. In conclusion, the oleogels studied could only be used in foods with a shelf life of less than 6 months.

Downloads

References

Americal Oil Chemists’ Society, 1990. Official methods and recommended practices of the American Oil Chemists’ Society. 4a ed. Champaign: AOCS. Official method Cd 8-53.

Blake, A. I. y Marangoni, A. G., 2014. Structure and physical properties of plant wax crystal networks and their relationship to oil binding capacity. En: J. Amer. Oil Chem. Soc., 91(6), pp. 885-903. DOI: https://doi.org/10.1007/s11746-014-2435-0

Buchwald, R.; Breed, M. D. y Greenberg, A. R., 2008. The thermal properties of beeswaxes: unexpected findings. En: Journal of Experimental Biology, 211(1), pp. 121–127. DOI: https://doi.org/10.1242/jeb.007583

Consejo Oleícola Internacional, 2019. Method of analysis. Spectrophotometric investigation in the ultraviolet. COI/T.20/Doc. No 19. [En línea]. Madrid: COI. [Consulta: 16 de febrero de 2023]. Disponible en: https://www.internationaloliveoil.org/wp-content/uploads/2019/11/Method-COI-T.20-Doc.-No-19-Rev.-5-2019-2.pdf

Dassanayake, L. S. K.; Kodali, D. R. y Ueno, S., 2011. Formation of oleogels based on edible lipid materials. En: Current Opinion in Colloid & Interface Science, 16(5), pp. 432–439. DOI: https://doi.org/10.1016/j.cocis.2011.05.005

Di Rienzo, J. A.; Casanoves, F.; Balzarini, M. G.; Gonzalez, L.; Tablada, M. y Robledo, C. W, 2020. InfoStat [En línea]. Versión 2020. Córdoba: Universidad Nacional de Córdoba. [Consulta: 20 de febrero de 2023]. Disponible en: http://www.infostat.com.ar

Doan, C. D.; Van der Walle, D.; Dwettinck, K. y Patel, A. R., 2015. Evaluating the oil-gelling properties of natural waxes in rice bran oil: Rheological, thermal and microstructural study. En: J. Amer. Oil Chem. Soc., 92(86), pp. 801-811. DOI: https://doi.org/10.1007/s11746-015-2645-0

Firestone, D., 2006. Physical and chemical characteristics of oils, fats, and waxes. 2a. ed. Champaign: AOCS Press.

Frolova, Y. V.; Sobolev, R. V.; Sarkisyan, V. A. y Kochetkova, A. A., 2021. Approaches to study the oxidative stability of oleogels. En: IOP Conference Series: Earth and Environmental Science, 677(3), 032045. DOI: 10.1088/1755-1315/677/3/032045

Gaudino, N., Ghazani, S. M.; Clark, S.; Marangoni, A.G. y Acevedo, N.C., 2019. Development of lecithin and stearic acid based oleogels and oleogel emulsions for edible semisolid applications. En: Food Res. Int., 116, pp. 79-89. DOI: https://doi.org/10.1016/j.foodres.2018.12.021

Giacintucci, V., Di Mattia, C. D., Sacchetti, G., Flamminii, F., Gravelle, A. J., Baylis, B., Dutcher, J. R., Marangoni, A. G. y Pittia, P., 2018. Ethylcellulose oleogels with extra virgin olive oil: the role of oil minor components on microstructure and mechanical strength. En: Food Hydrocolloids, 84, pp. 508-514. DOI: https://doi.org/10.1016/j.foodhyd.2018.05.030

Hwang, H. S.; Fhaner, M.; Winkler-Moser, J. K. y Liu, S. X., 2018. Oxidation of fish oil oleogels formed by natural waxes in comparison with bulk oil. En: Eur. J. Lipid Sci. Technol., 120(5), 1700378. DOI: https://doi.org/10.1002/ejlt.201700378

Hwang, H. S., 2020. A critical review on structures, health effects, oxidative stability, and sensory properties of oleogels. En: Biocatalysis and Agricultural Biotechnology, 101657. DOI: https://doi.org/10.1016/j.bcab.2020.101657

IUPAC, 1987. Standard methods for the analysis of oils, fats and derivatives. 7ma ed. Oxford: Blackwell. Method 2.301.

Luo, S. Z.; Hu, X. F.; Jia, Y. J.; Pan, L. H.; Zheng, Z.; Zhao, Y. Y.; Mu, D. D.; Zhong, X. Y.; Jiang, S. T., 2019. Camellia oil-based oleogels structuring with tea polyphenol-palmitate particles and citrus pectin by emulsion-templated method: Preparation, characterization and potential application. En: Food Hydrocoll., 95, pp. 76-87. DOI: https://doi.org/10.1016/j.foodhyd.2019.04.016

Martins, A. J., Cerqueira, F., Vicente, A. A., Cunha, R. L., Pastrana, L. M. y Cerqueira, M. A., 2022. Gelation behavior and stability of multicomponent sterol-based oleogels. En: Gels, 8(37), pp. 1-15, DOI: https://doi.org/10.3390/gels8010037

Patel, A. R.; Babaahmadi, M.; Lesaffer, A. y Dewettinck, K., 2015. Rheological profiling of organogels prepared at critical gelling concentrations of natural waxes in a triacylglycerol solvent. En: J. Agric. Food Chem., 63, pp. 4862-4869. DOI: https://doi.org/10.1021/acs.jafc.5b01548

Sagiri, S. S.; Singh, V. K.; Pal, K.; Banerjee, I. y Basak, P., 2015. Stearic acid based oleogels: a study on the molecular, thermal and mechanical properties. En: Mater Sci. Eng. C. Mater. Biol. Appl., 48, pp. 688-699, DOI: https://doi.org/10.1016/j.msec.2014.12.018

Shakeel, A.; Farooq, U.; Iqbal, T.; Yasin, S. y Lupi, F. R., 2019. Key characteristics and modeling of bigels systems: A review. En: Mater Sci Eng C Mater Biol Appl., 97, pp. 932-953, DOI: https://doi.org/10.1016/j.msec.2018.12.075

Sobolev, R.; Frolova, Yu; Sarkisyan, V.; Makarenko, M. y Kochetkova A., 2022. Effect of beeswax and combinations of its fractions on the oxidative stability of oleogels. En: Food Bioscience, 48, 101744. DOI: https://doi.org/10.1016/j.fbio.2022.101744

Toro-Vazquez, J. F.; Morales-Rueda, J. A.; Dibildox-Alvarado, E.; Charó-Alonso M.; Alonzo-Macias M. y González-Chávez, M. M., 2007. Thermal and textural properties of organogels developed by candelilla wax in safflower oil. En: J. Am. Oil Chem. Soc., 84(11), pp. 989-1000. DOI: https://doi.org/10.1007/s11746-007-1139-0

Uruguay. Ministerio de Salud Pública, 1994. Reglamento bromatológico nacional, decreto 315/994 [En línea]. Montevideo: IMPO. [Consulta: 14 de febrero de 2023]. Disponible en: https://www.impo.com.uy/bases/decretos-reglamento/315-1994

Yılmaz, E. y Öǧütcü, M., 2014. Oleogels of virgin olive oil with carnauba wax and monoglyceride as spreadable products. En: Grasas y Aceites, 65(3). DOI: https://doi.org/10.3989/gya.0349141

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Jimena Lázaro, Nadia Segura, Natalia Martínez, Bruno Alejandro Irigaray González

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Los autores del manuscrito declaran conocer y aceptar los siguientes términos de responsabilidad:

Haber participado lo suficiente en el trabajo como para hacer pública la responsabilidad por su contenido.

Que el manuscrito representa un trabajo original que no fue publicado ni está siendo considerado por otra revista para su publicación, en parte o en forma íntegra, tanto impresa como electrónica.

Que en caso de ser solicitado, procurará o cooperará en la obtención y suministro de datos sobre los cuales el manuscrito esté basado.

Declara que la información divulgada que pudiera pertenecer a un tercero cuenta con la autorización correspondiente.

Autorización para la publicación y compromiso de cita de primera publicación

Los autores/as conservan los derechos de autor y ceden a la revista INNOTEC / INNOTEC Gestión el derecho de la primera publicación, con el trabajo registrado con la licencia de atribución Creative Commons Reconocimiento-NoComercial 4.0 Internacional. Creative Commons, que permite a terceros utilizar lo publicado siempre que mencionen la autoría del trabajo y a la primera publicación en esta revista sin fines comerciales.

El autor se compromete a realizar la cita completa de la edición institucional de esta primer publicación en las siguientes publicaciones -completas o parciales- efectuadas en cualquier otro medio de divulgación, impreso o electrónico.

Los autores/as pueden realizar otros acuerdos contractuales no comerciales independientes y adicionales para la distribución no exclusiva de la versión del artículo publicado en esta revista (p. ej., incluirlo en un repositorio institucional o publicarlo en un libro) siempre que indiquen claramente que el trabajo se publicó por primera vez en esta revista.

Se permite a los autores/as publicar su trabajo en Internet (por ejemplo en páginas institucionales o personales) antes y durante el proceso de revisión, ya que puede conducir a intercambios productivos y a una mayor y más rápida difusión del trabajo publicado (vea The Effect of Open Access). A su vez los autores/as autorizan al LATU a publicar el trabajo en su repositorio digital.

Los conceptos y opiniones vertidos en los artículos son de responsabilidad de sus autores.

Este obra está bajo una licencia Reconocimiento-NoComercial 4.0 Internacional.