Technofunctionality of native and extruded Andean maize (Zea Mays) whole-grain flours

DOI:

https://doi.org/10.26461/24.02Keywords:

Andean grains, extrusion, techno-functional propertiesAbstract

Andean grains have great potential for transformation into new products, but their comprehensive utilization is a technological challenge. The objective of this work was to modify the techno-functional properties of whole-grain flours of the Capia, Bolita and Chulpi Andean maize races by extrusion to obtain flours that potentially improve the quality of gluten-free bread. The flours were extruded in a single screw extruder, using an incomplete orthogonal design with three levels of temperature, moisture and screw speed. The proximal composition of the native whole-grain flours was determined. In native and extruded flours were determined the water absorption index (IAA), water solubility index (ISA), oil absorption capacity (CRO), water binding capacity (CRA) and swelling volume (PH). The extruded Andean maize whole-grain flours presented significant differences in their composition. Most of the variability of data was due to moisture and extrusion temperature. In general, the samples of Capia and Bolita maize had a similar behavior, presenting higher IAA, CRA and pH at high moistures and temperatures; the ISA was higher at low moistures. The CRO did not show significant differences between treatments. Extruded whole-grain flour of Capia and Bolita maize with high IAA, CRA and PH, such as those obtained in the extrusion condition of 120 °C, 25 % H y 80 rpm, could improve the consistency of doughs and the softness of gluten-free breads.

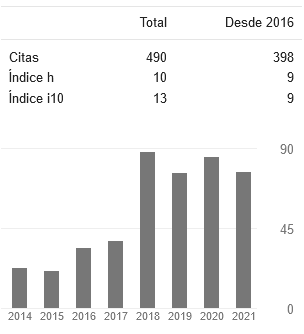

Downloads

References

Anderson, R.A., Conway H.F., Pfeifer V.F. y Griffin E.L, 1969. Gelatinization of corn grits by roll and extrusion cooking. En: Cereal Science Today, 14, pp.4-12. DOI: https://doi.org/10.1002/star.19700220408

AOAC International, 2005a. Official methods of analysis of AOAC International. 18 ed. Gaithersburg: AOAC. Official Method 925.10.

AOAC International, 2005b. Official methods of analysis of AOAC International. 18 ed. Gaithersburg: AOAC. Official Method 920.87.

AOAC International, 2005c. Official methods of analysis of AOAC International. 18 ed. Gaithersburg: AOAC. Official Method 920.39.

AOAC International, 2005d. Official methods of analysis of AOAC International. 18 ed. Gaithersburg: AOAC. Official Method 923.03.

Cámara Hernández, J. y Arancibia de Cabezas, D., 2007. Maíces andinos y su uso en la Quebrada de Humahuaca y regiones vecinas (Argentina). Buenos Aires: Facultad de Agronomía Universidad de Bs As. ISBN 978-950-29-1011-6.

Caputo, L., Visconti, A. y De Angelis, M., 2015. Selection and use of a Saccharomyces cerevisae strain to reduce phytate content of wholemeal flour during bread-making or under simulated gastrointestinal conditions. En: LWT-Food Science and Technology, 63(1), pp.400-407. DOI: https://doi.org/10.1016/j.lwt.2015.03.058

Chaudhary, A.L., Miler, M., Torley, P.J., Sopade, P.A. y Halley, P.J., 2008. Amylose content and chemical modification effects on the extrusion of thermoplastic starch from maize. En: Carbohydrate Polymers, 74(4), pp.907-913. DOI: https://doi.org/10.1016/j.carbpol.2008.05.017

Chen, H., Zhao, C., Li, J., Hussain, S., Yan, S. y Wang, Q, 2018. Effects of extrusion on structural and physicochemical properties of soluble dietary fiber from nodes of lotus root. En: LWT, 93, pp.204-211. DOI: https://doi.org/10.1016/j.lwt.2018.03.004

Clerici, M.T.P.S., Airoldi, C. y El-Dash, A.A., 2009. Production of acidic extruded rice flour and its influence on the qualities of gluten-free bread. En: LWT-Food Science and Technology, 42(2), pp.618-623. DOI: https://doi.org/10.1016/j.lwt.2008.08.010

Comettant-Rabanal, R., De Carvalho, C.W.P., Ascheri, J.L.R., Hidalgo Chávez, D.W. y Germani, R., 2020. Physical, textural and structural properties of gluten-free breads made from extruded whole grain flours [En línea]. En: Universidade Federal de São João del-Rei. Anais do Congresso on-line Brasileiro de Tecnologia de Cereais e Panificação. Sete Laogas, Brasil. Sete Lagoas: Universidade Federal de São João del-Rei. [Consulta: 2 de Julio de 2021]. Disponible en: http://www.alice.cnptia.embrapa.br/alice/handle/doc/1126445

Cornejo, F. y Rosell, C.M., 2015. Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. En: LWT-Food Science and Technology, 62(2), pp.1203-1210. DOI: https://doi.org/10.1016/j.lwt.2015.01.050

De Pilli, T. y Alessandrino, O., 2020. Effects of different cooking technologies on biopolymers modifications of cereal-based foods: Impact on nutritional and quality characteristics review. En: Critical Reviews in Food Science and Nutrition, 60(4), pp.556-565. DOI: https://doi.org/10.1080/10408398.2018.1544884

Di Rienzo, J.A, Casanoves, F., Balzarini, M.G., González, L., Tablada, M. y Robledo, C.W., 2008. InfoStat [En línea]. Versión 2017.1.2. Córdoba: Universidad Nacional de Córdoba. [Consulta: 5 de junio de 2021]. Disponible en: http://www.infostat.com.ar

Ding, Q.B., Ainsworth, P., Tucker, G. y Marson, H., 2005. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. En: Journal of Food engineering, 66(3), pp.283-289. DOI: https://doi.org/10.1016/j.jfoodeng.2004.03.019

Espinosa-Ramírez, J., Rodríguez, A., De la Rosa-Millán, J., Heredia-Olea, E., Pérez-Carrillo, E. y Serna-Saldívar, S.O., 2021. Shear-induced enhancement of technofunctional properties of whole grain flours through extrusion. En: Food Hydrocolloids, 111, 106400. DOI: https://doi.org/10.1016/j.foodhyd.2020.106400

FAO, 1993. El maíz en la nutrición humana. Roma: FAO. (Alimentación y nutrición, Nº 25). ISBN 92-5-303013-5.

Giménez, M.A., Gámbaro, A., Miraballes, M., Roascio, A., Amarillo, M., Sammán, N. y Lobo, M., 2015. Sensory evaluation and acceptability of gluten‐free Andean maize spaghetti. En: J Sci Food Agric., 95(1), pp.186-192. DOI: https://doi.org/10.1002/jsfa.6704

Gómez, M. y Martínez, M.M., 2016. Changing flour functionality through physical treatments for the production of gluten-free baking goods. En: J. Cereal Sci., 67, pp.68-74. DOI: https://doi.org/10.1016/j.jcs.2015.07.009

Kharat, S., Medina-Meza, I. G., Kowalski, R. J., Hosamani, A., Ramachandra, C. T., Hiregoudar, S. y Ganjyal, G. M., 2019. Extrusion processing characteristics of whole grain flours of select major millets (foxtail, finger, and pearl). En: Food and Bioproducts Processing, 114, pp.60-71. DOI: https://doi.org/10.1016/j.fbp.2018.07.002

Luo, S., Yan, X., Fu, Y., Pang, M., Chen, R., Liu, Y., Chen, J. y Liu, C., 2021. The quality of gluten-free bread made of brown rice flour prepared by low temperature impact mill. En: Food Chemistry, 348, pp.129032. DOI: https://doi.org/10.1016/j.foodchem.2021.129032

Moscicki L., 2011. Extrusion-cooking techniques: applications, theory and sustainability. Weinheim: WILEY-VCH Verlag & Co. ISBN: 978-3-527-32888-8.

Narváez-González, E.D., Figueroa Cardenas, J.D.D., Taba, S., Castaño Tostado, E. y Martínez Peniche, R.A., 2007. Efecto del tamaño del gránulo de almidón de maíz en sus propiedades térmicas y de pastificado. En: Revista Fitotecnia Mexicana, 30(3), pp. 269-277. ISSN: 0187-7380.

Paesani, C., Bravo-Núñez, Á. y Gómez, M., 2020. Effect of extrusion of whole-grain maize flour on the characteristics of gluten-free cookies. En: Lebensmittel-Wissenschaft und-Technologie, 132(1), pp.109931. DOI: https://doi.org/10.1016/j.lwt.2020.109931

Raghavendra, S.N., Rastogi, N.K., Raghavarao, K.S.M.S., y Tharanathan, R.N., 2004. Dietary fiber from coconut residue: effects of different treatments and particle size on the hydration properties. En: Eur Food Res Technol., 218(6), pp.563-567. DOI: https://doi.org/10.1007/s00217-004-0889-2

Raghavendra, S.N., Swamy, S.R., Rastogi, N.K., Raghavarao, K.S.M.S., Kumar, S. y Tharanathan, R.N., 2006. Grinding characteristics and hydration properties of coconut residue: A source of dietary fiber. En: Journal of Food Engineering, 72(3), pp.281-286. DOI: https://doi.org/10.1016/j.jfoodeng.2004.12.008

Roman, L., Gomez, M., Hamaker, B.R. y Martinez, M.M., 2018. Shear scission through extrusion diminishes inter-molecular interactions of starch molecules during storage. En: Journal of Food Engineering, 238, pp.134-140. DOI: https://doi.org/10.1016/j.jfoodeng.2018.06.019

Salvador-Reyes, R. y Clerici, M.T.P.S., 2020. Peruvian andean maize: general characteristics, nutritional properties, bioactive compounds, and culinary uses. En: Food Research International, 130, pp.108934. DOI: https://doi.org/10.1016/j.foodres.2019.108934

Sarifudin, A., y Assiry, A.M., 2014. Some physicochemical properties of dextrin produced by extrusion process. En: Journal of the Saudi Society of Agricultural Sciences, 13(2), pp.100-106. DOI: https://doi.org/10.1016/j.jssas.2013.02.001

Silvestre-De-León, R., Espinosa-Ramírez, J., Heredia-Olea, E., Pérez-Carrillo, E. y Serna-Saldívar, S.O., 2020. Biocatalytic degradation of proteins and starch of extruded whole chickpea flours. En: Food and Bioprocess Technology, 13(10), pp.1703-1716. DOI: https://doi.org/10.1007/s11947-020-02511-z

Stephen, A.M. y Phillips, G.O., 2006. Food polysaccharides and their applications. 2a edición. Boca Raton: CRC Press.

Tsatsaragkou, Κ., Protonotariou, S. y Mandala, I., 2016. Structural role of fibre addition to increase knowledge of non-gluten bread. En: Journal of Cereal Science, 67, pp.58-67. DOI: https://doi.org/10.1016/j.jcs.2015.10.003

Wang, J., Suo, G., de Wit, M., Boom, R.M. y Schutyser, M.A., 2016. Dietary fibre enrichment from defatted rice bran by dry fractionation. En: Journal of Food Engineering, 186, pp.50-57. DOI: https://doi.org/10.1016/j.jfoodeng.2016.04.012

Zhang, H. y Xu, G., 2019. Physicochemical properties of vitreous and floury endosperm flours in maize. En: Food Science & Nutrition, 7(8), pp.2605-2612. DOI: https://doi.org/10.1002/fsn3.1114

Zhong, L., Fang, Z., Wahlqvist, M.L., Hodgson, J.M., y Johnson, S.K., 2019. Extrusion cooking increases soluble dietary fibre of lupin seed coat. En: LWT, 99, pp.547-554. DOI: https://doi.org/10.1016/j.lwt.2018.10.018

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Rita Marisol Miranda, Natalia Ester Domínguez, María Alejandra Giménez, Manuel Oscar Lobo, Norma Cristina Sammán

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Los autores del manuscrito declaran conocer y aceptar los siguientes términos de responsabilidad:

Haber participado lo suficiente en el trabajo como para hacer pública la responsabilidad por su contenido.

Que el manuscrito representa un trabajo original que no fue publicado ni está siendo considerado por otra revista para su publicación, en parte o en forma íntegra, tanto impresa como electrónica.

Que en caso de ser solicitado, procurará o cooperará en la obtención y suministro de datos sobre los cuales el manuscrito esté basado.

Declara que la información divulgada que pudiera pertenecer a un tercero cuenta con la autorización correspondiente.

Autorización para la publicación y compromiso de cita de primera publicación

Los autores/as conservan los derechos de autor y ceden a la revista INNOTEC / INNOTEC Gestión el derecho de la primera publicación, con el trabajo registrado con la licencia de atribución Creative Commons Reconocimiento-NoComercial 4.0 Internacional. Creative Commons, que permite a terceros utilizar lo publicado siempre que mencionen la autoría del trabajo y a la primera publicación en esta revista sin fines comerciales.

El autor se compromete a realizar la cita completa de la edición institucional de esta primer publicación en las siguientes publicaciones -completas o parciales- efectuadas en cualquier otro medio de divulgación, impreso o electrónico.

Los autores/as pueden realizar otros acuerdos contractuales no comerciales independientes y adicionales para la distribución no exclusiva de la versión del artículo publicado en esta revista (p. ej., incluirlo en un repositorio institucional o publicarlo en un libro) siempre que indiquen claramente que el trabajo se publicó por primera vez en esta revista.

Se permite a los autores/as publicar su trabajo en Internet (por ejemplo en páginas institucionales o personales) antes y durante el proceso de revisión, ya que puede conducir a intercambios productivos y a una mayor y más rápida difusión del trabajo publicado (vea The Effect of Open Access). A su vez los autores/as autorizan al LATU a publicar el trabajo en su repositorio digital.

Los conceptos y opiniones vertidos en los artículos son de responsabilidad de sus autores.

Este obra está bajo una licencia Reconocimiento-NoComercial 4.0 Internacional.